Oracle, one of the world’s largest companies, announced new capabilities for their Oracle Cloud enterprise platform that’s designed to give large businesses a bird’s-eye view of their entire operation through comprehensive monitoring of digital and physical assets. Along with the new capabilities the company demonstrated how AR and VR can be leveraged for added intelligence.

Enterprise IoT

The Internet-of-Things, or IoT, roughly describes bringing connected capabilities to objects that traditionally didn’t have any need to communicate over a network. Wifi-connected smart fridges, smart speakers, and even robot vacuum cleaners are all examples of IoT in the consumer space. When it comes to large scale enterprises, IoT objects might be pumps, trucks, motors, conveyor belts, and more. Enabling such devices to relay real-time information can offer businesses a comprehensive view of their operations, all the way from a single forklift on the factory floor to a overview of manufacturing plants spanning multiple countries.

Oracle Cloud

By 2018 Oracle expects 50 billion IoT devices on the market, but the company says that finding value from IoT is challenging for businesses because of implementation challenges and ambiguous ROI. Naturally, Oracle wants to help businesses integrate IoT into their operations, and hopes to make it easy for customers to achieve real outcomes with the technology. The company points to the following broad use-cases:

- Asset Monitoring: Monitor assets, health, utilization, and availability

- Production monitoring: Manufacturing equipment and production line monitoring and prognostics

- Fleet monitoring: Monitor shipments, fleet vehicles, driver behavior and costs

- Connected worker: Enhance worker safety through monitoring of workers and environment

In a meeting at the company’s Silicon Valley headquarters last week, Oracle introduced new features coming to their IoT platform and showed me several examples of how an IoT integrated business can be more efficient.

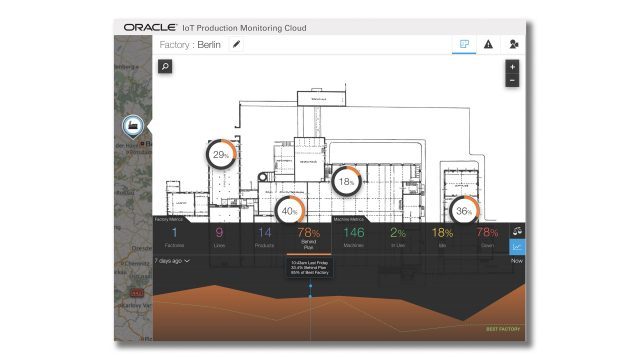

Top to Bottom Business Intelligence

In one example, the Oracle Cloud platform showed a manufacturing manager the status of three factories across the globe. On the software’s dashboard, the manager can see at a glance high level statistics like how close each factory was to meeting its production schedule. With one factory being notably behind the others, the company showed how it was easy to drill down to the individual factory view to see statistics about the each part of the production line.

From this view it became clear that one of the machines responsible for testing the product toward the end of the line was creating a bottleneck in the factory’s output. Because the machine is IoT enabled, a manager is able to pull up info on that specific machine and see that it is running the wrong program, causing it to test the products for longer than it was supposed to and creating a backup in the production line. The manager was able to immediately submit a ticket to ask a technician in the factory to make the proper adjustment to that specific machine. Pretty snazzy.

All of this happened from the Oracle Cloud dashboard running on a tablet, highlighting the potential power and convenience of an IoT connected business. The above was made possible with new Digital Twin, Digital Thread, and artificial intelligence and machine learning features that the company is adding to their platform. They also demonstrated AR and VR visualization capabilities which draw upon the data fed into the IoT platform.

VR Visualization and Training

When it comes to VR, Oracle showed how a headset like Gear VR could be used to tour the ‘Digital Twin’ of a factory floor, allowing the user to walk around a matching virtual version of a real factory floor. The virtual machines reflected the data from their real-life counterparts, offering up information like uptime, downtime, temperature, and other vitals.

The value to this particular visualization wasn’t immediately apparent to me, as gathering the same data seemed like it would be easier from a simple top down or isometric view on a flat screen. However, it’s clear that the VR approach could make it easier for less technical workers to browse the factory floor by relying on their mental map if the space, rather than needing to learn how to navigate around a new piece of software.

Where the VR visualization became more interesting and had a clearer value proposition was a demonstration of how it could be used for training. Because the Digital Twin capabilities mean that a business would likely already have a virtual replica of many of their facilities, offering a way for workers to train in a virtual version of the actual building, and on the actual machine that they will eventually work on, could be an intuitive way to educate new employees. For existing employees, the system could also be used to train them on equipment that hasn’t yet been installed, allowing them to get up to speed before the equipment arrives.

From a design standpoint, the training example shown on Gear VR was rudimentary compared to what you might expect from most of today’s consumer VR content—and consisted mostly of point and click step by step operations—but as far as I understand, there’s really no limit to how detailed the experience could be made; it comes down to how much detail and interaction each business wants to build into their training applications.

AR for Data at a Glance, Interactive Instructions

The AR example also showed a clear value proposition. To show what an IoT connected business could do with the platform and an AR device, a 3D printed model of an industrial pump was used as a prop representing a real pump in a factory. Using a tablet as a stand-in for future enterprise AR headsets, the company showed how the device could identify the pump from barcode-like marker on the unit, allowing it to overlay a model of the device onto the display, offering up real-time information relayed through the Oracle Cloud IoT system.

In addition to seeing the pump’s vitals at a glance, it was also possible to overlay repair schematics offering interactive disassembly instructions rather than relying on paper documentation to get the job done. Using a tablet for this isn’t that convenient, but it’s easy to see how the same functionality via an always-on pair of AR glasses would be a major step forward for this kind of data visualization.

– – — – –

Oracle’s AR and VR integrations with their IoT cloud feel tangible but preliminary, though it was clear from my time with the company that they’re enthusiastic about the possibilities that the technologies provide. I also get the sense that they’re waiting on proper enterprise-ready headsets (both AR and VR) as they mature their integration with the tech.